PLASTIC RECYCLING MACHINE

Model: RK3160-WDC-1

Capacity:900-1100 KG/HR

Filter: Auto back-flush filter

Time Machine for Plastics™

我們製造時光機,讓塑料回到過去或未來™

Making future plastic & Bring the virgin plastic back

Twin-screw extrusion system & Plastic recycling machines

We make Machines

Plastic recycling equipment / Twin screw compounding extruder /Auxiliary machine

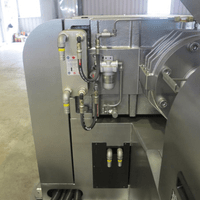

AUTO SCREEN CHANGER WITH BACK FLUSH SYSTEM

SAVE YOUR TIME AND ENERGY, PURITY YOUR MATERIAL

- 2 Pistons / 4Pistons are available

- Controlled by pressure gauge

- Increase the venting/degassing effect

- Can be equipped before the vent

TWIN-SCREW COMPOUNDING SYSTEM

AVAILABLE FOR PA/ABS/PLA/GF

- Multi-feeding system

- Precision temperature control

- Modified pelletizing system

- For thermoplastic compounding of plastic carrier with color pigment, magnetic, calcium carbonate, glass fiber, carbon and other additives.

- For recycling of high temperature plastics

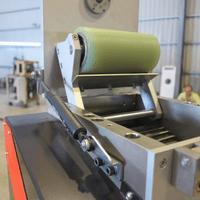

WATER PLATE PELLETIZING SYSTEM

Special For PET/PA/PC

- Patented system

- Pull-free strand cutting

- Taiwan No.1 modified operation pelletizing system

- Easy to assemble and maintain

- One set design from pelletizing to de-watering

RK 3065-WDC3

Model: RK3065-WDC3

Application: PP Film and HDPE Film

Type: Water Ring/ Die Head Pelletizing

Spec.: Screw Dia.65mm

Capacity:80-120 KG/HR

Filter: Double Plates

RK 1065-UWC4

Model: RK1065-UWC4

Application: TPU plastic recycling

Type: Underwater Pelletizing

Spec.:Screw Dia.65mm

Capacity:80-120 KG/HR

Filter: Single PlateRK 3160-WDC1

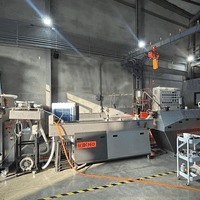

Model: RK3160-WDC1

Application: LDPE, HDPE Film

Type: Water Ring/ Die Head Pelletizing

Spec.: Screw Dia.160mm

Capacity:900-1100 KG/HR

Filter: Auto back-flush filter

RK 1065-UWC4

Model: RK1065-UWC4

Application: TPU plastic recycling

Type: Underwater Pelletizing

Spec.:

Screw Dia.65mm

Capacity:80-120 KG/HR

Filter: Single PlateRK 2032-UWC4

Model: RK2032-UWC4

Application: TPR, PP

Pellet Type: Underwater Pelletizing

Spec.: Screw Dia.32mm

Capacity:80-120 KG/HR

Filter: Single Plate

We are REKNO

Our Promise is Steel™

鋼諾,給客戶鋼鐵般的承諾™

NO. Two in Asia

Plastic recycling machine

亞洲第二的廢塑料回收設備

Taiwan No.1 Plastic recycling machine manufacturer.

REKNO's plastic recycling machine is equipped with the best filtering system of Taiwan, it can non-stop working and filter out the impurities effectively to increase approximately 20% capacity, and lower 10% loss.

REKNO的塑料回收設備配有台灣最好的過濾系統,

能更有效地過濾雜質並且不斷料,使機器效能提升至少20%,並降低10%已上的損耗。

The One of the Best in Taiwan

Twin-Screw Compounding System

雙螺桿複合材料押出設備

Custom design for customer to do thermoplastic compounding of plastic carrier with color pigment, magnetic, calcium carbonate, glass fiber, carbon and other additives and recycling of high temperature plastics such as POM,PPO,PA......

為不同需求來客製化設計雙螺桿押出設備,讓客戶能夠處理各種不同配方的特殊原料,例如尼龍加玻璃纖維、特殊防火材質、高比例碳酸鈣混煉以及PLA生物可分解塑膠等等。

Now is Future

創業沿革

With more than 30 years experience in extruder manufacturing.

In the past, our work team is used to do OEM/ODM for other companies in Taiwan, but REKNO Industrial company is now brand our own brand from November 2016.

We do't want to limited by the past experience, we're going to make the new generation machines through the big data of customer feedback and in-house testing.

機械製造經驗超過三十年。

鋼諾工業股份有限公司,曾為台灣許多品牌機械工廠代工生產機器設備,於2016年11月開始建立屬於自己的品牌事業。我們不設限、不依賴過往的經驗,而是經由累積的資料、大量試驗數據及客戶實際生產的回饋來改善我們的設備。

Goal and Mission

目標與展望

To be TOP1 in Asia, the world class recycling machine manufacturer.

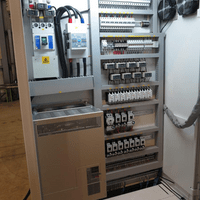

REKNO is cooperate with Siemens, Speck, Zambello and JFE. Making design and manufacturing in Taiwan to ensure the quality and cost to offer the best C/P value for our good customers.Our goal is to become NO.1 extrusion system of compounding(Twin screw) and recycling(Single screw) manufacturer in Asia.

亞洲第一、台灣第一、世界級的塑膠回收造粒設備

鋼諾與德國西門子Siemens合作的節能押出系統、Speck的高效真空抽氣設備、與義大利Zambello章貝鉻開發的專用齒輪箱、日本技術的合金螺桿以及台灣設計製造的切粒設備、控制系統。

我們的目標是成為亞洲第一、世界級的雙螺桿押出及塑膠回收造粒設備供應商。Plastic Recycling Pelletizing Process

1Input Material

- Film/Raffia/Bags

- Flakes/Regrinds

- Injections/Lumps/Pipes

- Non-woven/Foamed

- Ropes/straps

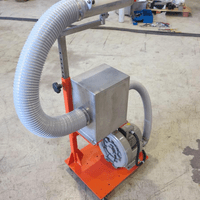

2Crushing and Feeding

- 3-in-1 type

- Directly feeding

- Conveyor+Crusher

3Extruding and Vacuum Degassing

- Single Vacuum Degassing

- Double Vacuum Degassing

- Triple Vacuum Degassing

- Vent

4Filtering

- Auto Screen Changer

- Back-flush system

- Double Plates

- Quadruple Plates

- Double Pistons

- Quadruple Pistons

- Full filter area design

5Pelletizing

- Strand type

- Water Ring type

- Underwater type

- Water plate type

- Air cooling type

6Pellets

- PA/PET/PC

- PE/PP

- PS/ABS

- EVA/TPU/TPE/TPR

- PVC

- EPS/EPE/EPP

Machine Photos

Photos & videos from our customers / in our factory

Contact Info

鋼諾工業股份有限公司 REKNO INDUSTRIAL CO., LTD.

台灣新北市林口區民享路408號

No. 408, Min Shan Rd., Lin Ko Dist., New Taipei, Taiwan.Tax I.D.:65647609

TEL.:+886-2-26018588

Email:rekno.sales@gmail.com- Sales Manager:Miss Lucy Wu(吳佳紋)

- Australia office:Mr. Blanch(www.alliedANZ.com.au)

- Europe office:Mr. Marius

- India office:Anil International (www.AnilAssociates.com)

- South America office:WANTED

- Vietnam office:WANTED

- Philippine office:WANTED

Copyright©REKNO Industrial Co., Ltd. 2016

Om Ma Ni Bä Mê Hum‧इति प्रज्ञापारमिताहृदयं समाप्तम्

南無山滿多,莫渡難,翁,渡路渡路,地維娑婆訶

翁,大裂,渡大裂,大裂,渡裂,莎訶